Service Environmental solutions

We support GX (Green Transformation), which is the transformation of the entire economic and social system through efforts to realize a decarbonized society.

We can flexibly respond to proposals for environmental improvement and energy conservation at manufacturing sites and assistance with subsidy applications.

Career field

-

Air conditioning

solutions -

Optimization of

compressed air -

Energy solution

-

Water environment

solutions -

Grant Proposal

Case Study Examples of environmental solutions

Case 1 Air conditioning solutions

Reduce electricity costs by up to 50% by installing a personal air conditioning system

Conventional factory-wide air conditioning systems have had the problem of excessive investment and energy costs. Therefore, we proposed the ``Multi-Cube Air Conditioner,'' a personal air conditioning system that targets the worker's activity range and cools and heats them individually. Unlike conventional air conditioners that condition the entire space, multi-cube air conditioners can be used flexibly to suit the required work space. This allows air conditioning to be applied to the required space as much as necessary, leading to rational environmental improvements. The whole air conditioner can now be operated at 30 to 50% of the electric capacity and cost.

Case 2 Optimization of compressed air

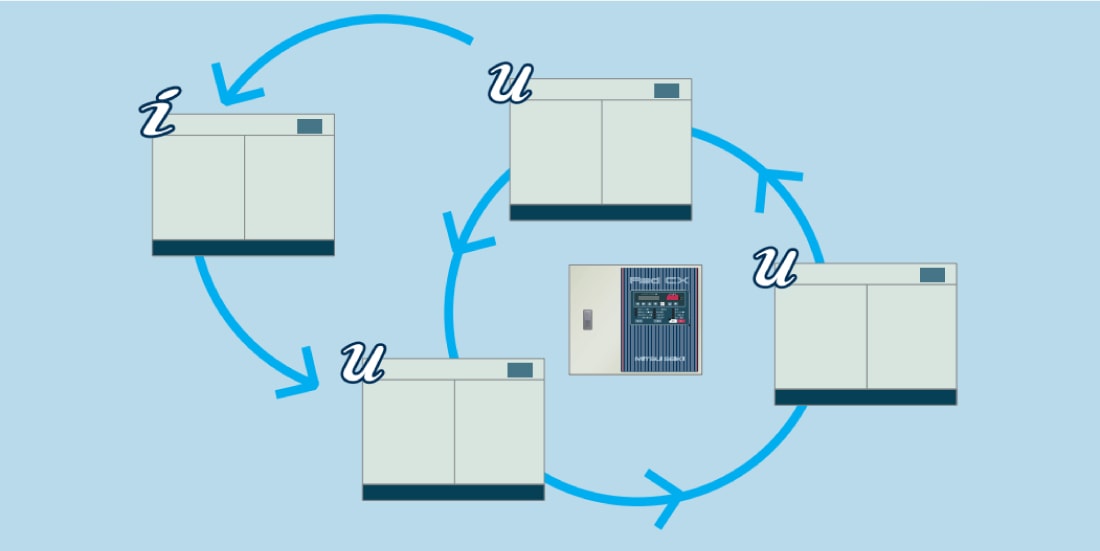

Controlling the number of compressors in operation greatly improves energy saving efficiency

A production factory within the prefecture that primarily handles cutting. Due to the expansion of business and the construction of a new factory, air usage is on the rise. In order to solve this problem, we have previously operated with two 37kW oil-fed compressors, but we will be increasing the number of 37kW oil-fed compressors to a total of three in order to improve operational maintainability and add backup functions. Suggest something. We have also added a function to control them together.

The biggest advantage of controlling the number of machines is that it allows operation with the optimal number and system (combination of constant speed machines and inverter machines) at all times, depending on the factory's production status and changes in air consumption. In this case, we used "rotation operation" to average the operating time of the three devices. We received high praise for our success in energy savings that exceeded that achieved by inverter control.

Case 3 Energy solution

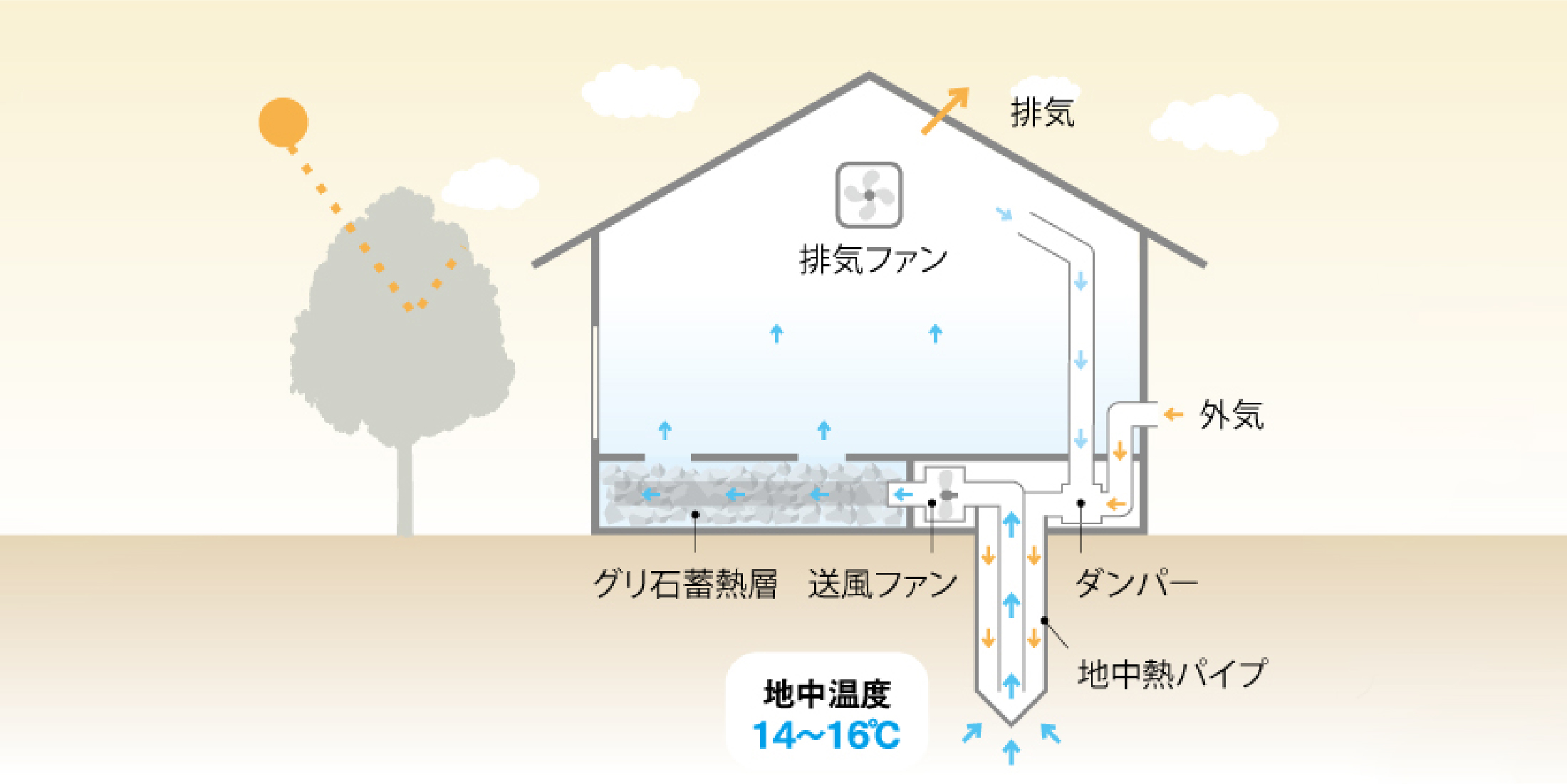

Creating a comfortable space using geothermal heat

We are considering air conditioning equipment for a new factory, and issues include the scale of investment, energy costs, and decarbonization for conventional air conditioning equipment. Therefore, we proposed an air-conditioned environment using GEO spots that utilize natural energy "geothermal heat." GEO Spot, a geothermal spot air conditioner for factories, is a system that utilizes geothermal heat from relatively shallow geological formations using heat exchange pipes. In the summer, outdoor air is cooled using geothermal heat at approximately 15-17°C before being blown into the factory, creating a clean air-conditioned environment with no waste heat.

For other cases, please contact us below.

Contact